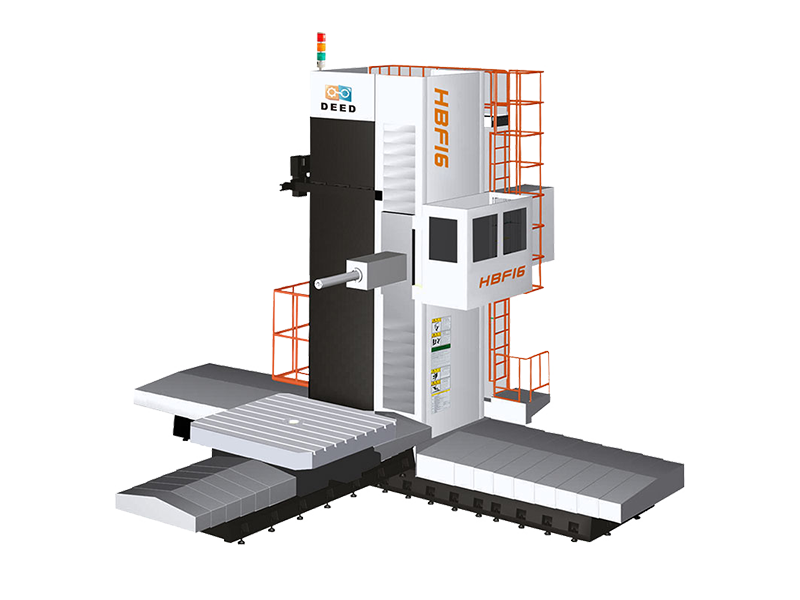

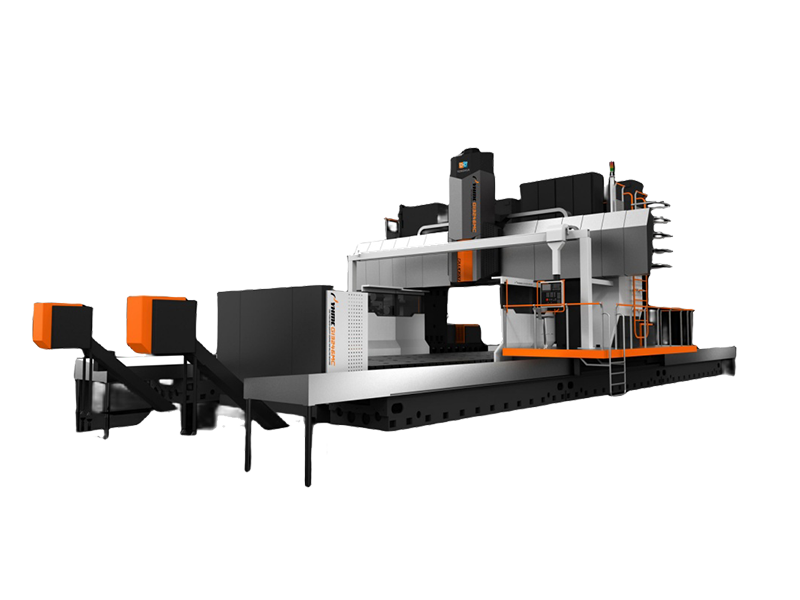

G-MC series moving column gantry boring and milling machining center

Product features

The G-MC series moving column gantry boring and milling machining center has the structural characteristics of high power, high torque, large stroke, high precision, high rigidity, heavy cutting, strong bearing capacity, and small footprint. It has functions such as milling, boring, drilling, tapping, spot facing, and three-axis linkage machining, and is widely used for the processing of medium and large parts in industries such as energy, engineering, casting, railway and transportation, aerospace, weapons, and ships.Configuration

Technical parameters of G-MC series moving column gantry boring and milling machining center

Project | Unit | G13042MC | G15042MC | G17042MC | G19042MC | |

Machine range | X/Y/Z three-axis travel | mm | 13000/4600/1500 | 15000/4600/1500 | 17000/4600/1500 | 19000/4600/1500 |

Spindle nose table surface | mm | 500-2000 | 500-2000 | 500-2000 | 500-2000 | |

Door width | mm | 4200 | 4200 | 4200 | 4200 | |

Staging | Workbench size | mm | 12000×3000 | 14000×3000 | 16000×3000 | 18000×3000 |

t/m | 10 | 10 | 10 | 10 | ||

T-slot | mm | 28 | 28 | 28 | 28 | |

Feed | X/Y/Z axis fast movement speed | m/min | 10/10/10 | 10/10/10 | 10/10/10 | 10/10/10 |

Maximum cutting speed of X/Y/Z axis | m/ min | 6/6/6 | 6/6/6 | 6/6/6 | 6/6/6 | |

Main shaft | Driving method | Maximum load capacity of workbench | Maximum load capacity of workbench | Maximum load capacity of workbench | Maximum load capacity of workbench | |

spindle taper | BT50 | BT50 | BT50 | BT50 | ||

| Maximum speed | r/min | 4500 | 4500 | 4500 | 4500 | |

Power (rated/30min) | KW | 30/37 | 30/37 | 30/37 | 30/37 | |

Torque (rated/30min) | Nm | 1368/1688 | 1368/1688 | 1368/1688 | 1368/1688 |

Video

Application

Standard Configuration

CNC system FANUC0i-MF

Spindle constant temperature system

Automatic Lubrication System

Z-axis balance system

Workpiece air cooling system

Workpiece water cooling system

Automatic chip removal device

Internal protection

External protection

Cleaning air gun

Warning lights

Work lights

Electric cabinet air conditioning

Dust prevention of spindle air curtain

Standard accessory

X-axis grating ruler

Which option is most suitable for you?

SIEMENS 828D

SIEMENS ONE

Circular knife magazine 24T/30T

Chain tool magazine 32T/40T

Vertical and horizontal knife storage 40T/60T

Increase the overall height of the column by 200mm

Column height increase by 400mm

Z-axis stroke change

Center effluent(20/30/50bar)

Voltage regulator

Y/Z full closed-loop grating ruler

Oil water separation device

Manual accessory milling heads: right angle head, extension head, universal head, right angle extension head, double end right angle milling head, vertical and horizontal head, optional tooth disc positioning

Automatic/semi-automatic accessory milling heads: right angle head, extension head, universal head, right angle extension head

Automatic measuring device for workpieces

Automatic tool measuring device

Workpiece cleaning water gun

Spindle ring spray

Foundation subsidence

CNC rotary worktable (fourth axis)

Closed operating room

Location:

Location:

Home

Home

Products

Products

Mod

Mod